PET - Manipulation description (step 1-3)

The only automatic batching unit that does not need any heavily shielded working cell!!! Original patented system avoids any unshielded manipulations with FDG. Patented system avoiding unexploited rests of expensive active solution in the vial thus saving considerable amount of money!! The very efficient patented system reduces secondary costs to a minimum as well as the whole time needed for manipulation. You save money and you have better irradiation protection at the same time. You do not need a big hot cell with 50mm Pb shielding to prepare doses for patients! The batching unit is the most compact one and does not need any additional shield.

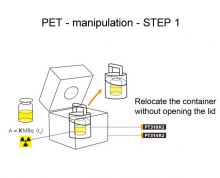

Step 1

The activity is transported from the laboratory to the NM department inside the Packaging set Type A for transport of radioactive solutions PT314R2. It consists of the outer case and the inner tungsten container PT318R2. The packaging set is located next to the working place. It is a laminar flow cell or just a simple workbench where the Automatic batching and measuring device PT317R3 is located. The lead castle is not necessary while working with the device PT317R3.

The inner tungsten container PT318R2 with 28mm of W is taken out of the outer case and without opening the lid transported into the socket of the Automatic batching and measuring device PT317R3.

Step 2

The lid of the PT318R2 is open manually and two needles are introduced into the vial - a breathing needle (bent) and a suction needle. The vial being in a slanted position the edge of the suction needle comes exactly into the lowest inner point of the vial. This patented configuration avoids the rests.The container PT318R2 now with two needles introduced into the rubber lid of the vial is subsequently plugged into the body of the batching device PT317R3. The cone (head) of the needle comes exactly between the fastening jaws of the chucking head and is fixed manually by a screw. The value of the activity in the vial and the respective time must be entered into the daily program of the control computer.

The activity of FDG in the vial is being calculated by the control computer during the batching procedure. The value of the activity remaining in the vial shows the display of the control computer continuously.

The device is now prepared for withdrawing the radioactive solution into the syringe. The whole procedure has been made without extracting the vial from the shielding container PT318R2 which is a component part of the Packaging set Type A PT314R2 and for the procedure of batching becomes also a part of the Batching and measuring device PT317R3.

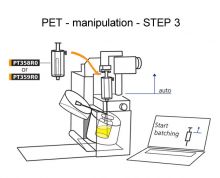

Step 3

The syringe (Braun OMNIFIX) inside the tungsten shielding PT358R5 or PT359R5 is located into the cylindrical socket of the upper part of the PT317R3. The angular position of the shield is defined by a small groove on its external surface. The groove being small and located on the rim of the shield it does not restrain the shielding qualities.

The syringe is connected to the needle by means of the thread in the head of the syringe by rotating the syringe manually.

The lifting fork of the batching device is connected to the outer end of the syringe piston manually. This operation is very simple and needs about 3 seconds. The hand of the radiopharmacist does not touch the piston.

The controlling of the functions is carried out using a control laptop. The crew selects the activity to be drawn into the syringe and starts the batching.